Variable Frequency Drives (VFDs) play a crucial role in modern industrial processes by controlling the speed of electric motors. However, like any other electrical component, VFDs are prone to wear and tear over time, requiring repair and maintenance to ensure optimal performance. In this guide, we will delve into the intricacies of VFD repair, highlighting key aspects and best practices.

What is a Variable Frequency Drive (VFD)?

A Variable Frequency Drive (VFD) is a type of motor controller that drives an electric motor by varying the frequency and voltage supplied to the motor. This enables precise control over the motor’s speed, making VFDs essential in applications requiring variable speed control, such as HVAC systems, pumps, and conveyor belts.

Common VFD Issues Requiring Repair

- Overheating: Excessive heat can damage VFD components, leading to malfunction. Regular maintenance and cooling systems are crucial to prevent overheating.

- Electromagnetic Interference (EMI): EMI can disrupt VFD operation, leading to erratic behavior. Proper grounding and shielding are necessary to mitigate EMI issues.

- Faulty Capacitors: Capacitors are essential components in VFDs, and their failure can result in erratic motor behavior or complete VFD failure. Regular inspection and replacement of capacitors are recommended.

- Input Power Issues: Fluctuations or interruptions in input power can damage VFDs. Surge protection and a stable power supply are essential to prevent damage.

- Software and Firmware Updates: Regular updates to VFD software and firmware are crucial to ensure optimal performance and compatibility with other systems.

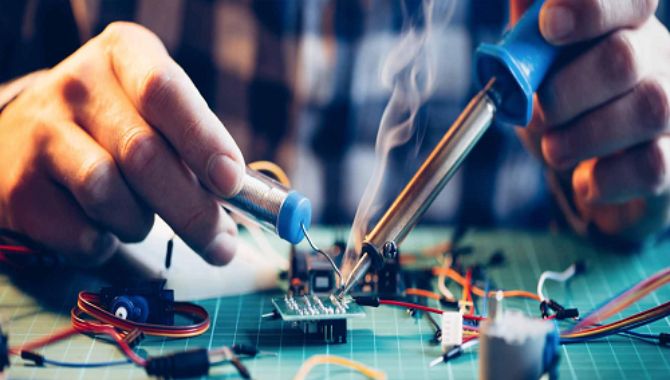

Repairing a Variable Frequency Drive

- Diagnosis: Thoroughly diagnose the VFD to identify the root cause of the issue. This may involve testing components, checking connections, and reviewing error codes.

- Component Replacement: Replace faulty components such as capacitors, resistors, or damaged circuit boards. Ensure replacement parts are compatible with the VFD model.

- Software/Firmware Updates: Update VFD software and firmware to the latest version to address known issues and improve performance.

- Testing and Calibration: After repair, test the VFD to ensure it is functioning correctly. Calibrate settings such as motor speed and acceleration to meet the application requirements.

Preventive Maintenance and Best Practices

- Regular Inspections: Conduct inspections of VFDs to identify potential issues before they escalate.

- Temperature Monitoring: Install temperature sensors to monitor VFD temperature and prevent overheating.

- Proper Installation: Ensure VFDs are installed correctly, following manufacturer guidelines and electrical codes.

- Training and Education: Provide training to personnel on VFD operation, maintenance, and safety practices.

Conclusion

Understanding the nuances of VFD repair is essential for ensuring the longevity and efficiency of industrial processes. By following best practices and implementing preventive maintenance measures, you can minimize downtime and maximize the lifespan of your VFDs.

For professional VFD repair services, consider contacting Swastika, a trusted provider in the field. With their expertise and commitment to quality, Swastika can help you keep your operations running smoothly.